What is Chip Load & Why It’s Important

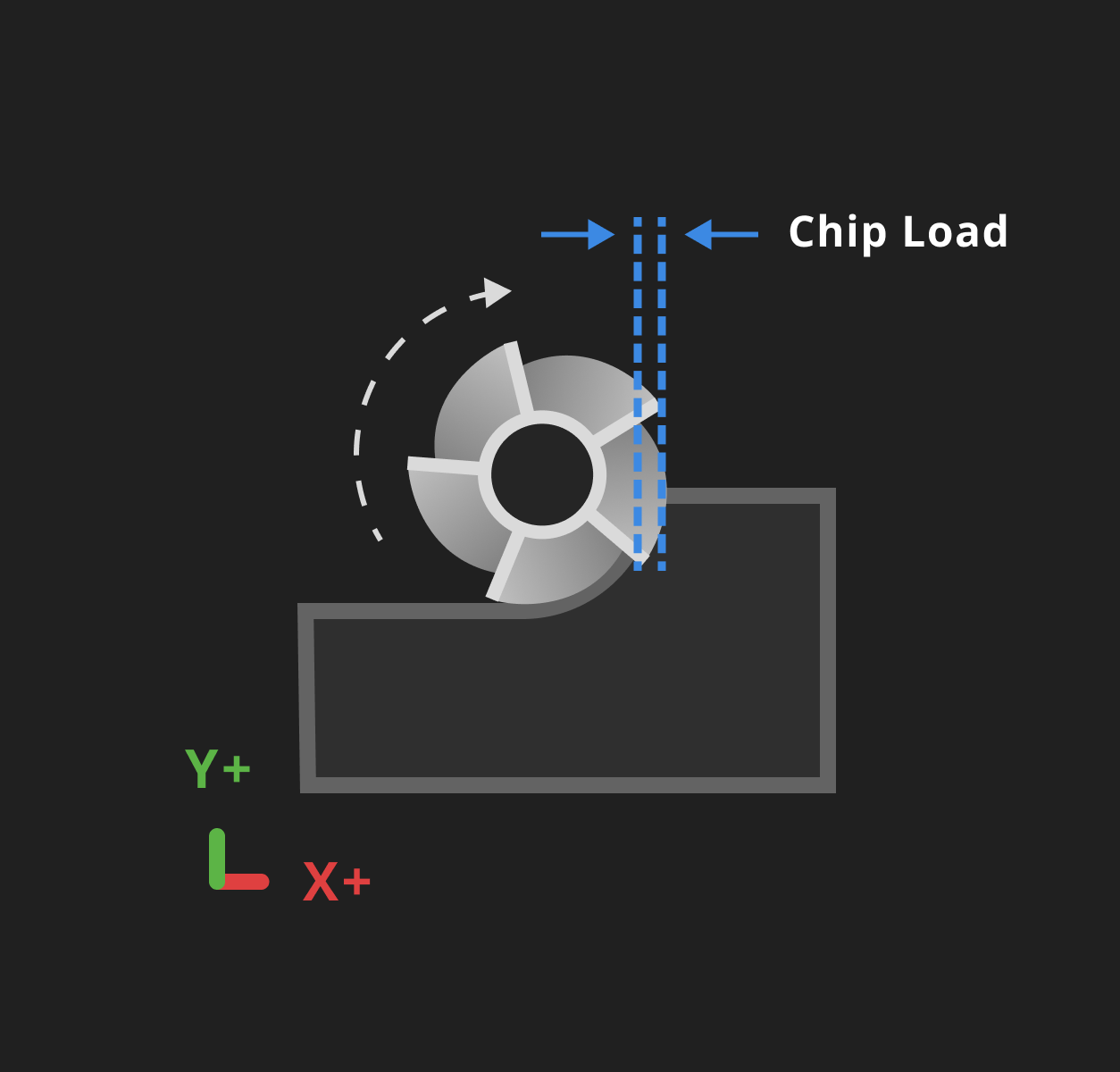

Chip load is the size of the piece of material you make when your end mill cuts into it. The size of the chips you make is important to calculate and note while machining because this can impact the efficiency of your cut, the lifespan of your end mill, and the quality of your parts.

There are two types of chip load: chip load per tool and then chip load per tooth—aka “feed per tooth.” Chip load per tool is the amount of material removed by the entire tool, while the feed per tooth is the amount of material being removed by each individual flute (or tooth) on your end mill.

Not optimizing (or paying attention) to chip load can lead to poor surface finishes, breaking your tool, chip welding, machine cashes, and, sometimes, all the above. Here are two common scenarios:

Chips are so large they don’t evacuate fast enough, which can lead to tools breaking.

Chips that are so small they can’t handle the heat distribution so they weld to the tool.

If you’re in the middle of running a job it can be difficult to tell if a tool has welded. In our experience, you will hear that something is wrong before you see something is wrong. This why developing a machinist’s ear is useful and why you don’t want to walk away from your machine while it’s cutting.

Uncoated carbide end mill with aluminum welded onto it.

Note: If you’re new to CNC machining: A “machinist’s ear” is the art of listening to a cut a know if it’s good, bad, and even being able to tell how to make adjustments to the speeds and feeds on the fly. With time and practice, this is a tool you can develop.

Calculating Chip Load

To better manage your chip load, take a closer look at the speeds and feeds you’re programming. Dialing in your speeds and feeds based on the machine you’re using, the end mill you’ve installed, the material you’re cutting, and the type of operation you’re cutting all plays a factor when developing speeds and feeds recipes. A quick Google search will lead you to a number of different formulas to help you reach a starting point for a recipe. You can also go to a tooling manufacturer’s website for more data.

Sidenote: If you’re a Bantam Tools user, you can find baseline recipes in our Fusion 360 Tool Library and the Bantam Tools software’s built-in Tool Library

Specifically for chip load, this is the formula to calculate it.

Note: In this example, “RPM” stands for spindle speed.

As you gain more experience as a machinist or with a mill like the Bantam Tools Desktop CNC Milling Machine, finding the balance between what you’re seeing and hearing while your cutting and the data will ultimately help you develop go-to recipes, extend the life of your tooling, and consistently turn out high-quality parts.

At Bantam Tools, we build desktop CNC machines with professional reliability and precision to support world changers and skill builders. For the latest Bantam Tools news, sign up for our newsletter. You can also follow us on LinkedIn, YouTube, Instagram, Facebook, or Twitter. If you’re interested in adding a Bantam Tools machine to your workflow you can order directly from our online store or request a quote.