Replacement Parts for the Bantam Tools Desktop CNC Milling Machine

We designed the Bantam Tools Desktop CNC Milling Machine with precision and reliability. But, like any CNC machine, there are going to be parts that wear out over time. How quickly these items need to be replaced depends on a number of factors, including the number of machining hours, if you’re regularly cutting unsupported materials, speeds and feeds you’re programming, and your attention to cleaning and maintenance. Common wear parts on the Bantam Tools Desktop CNC Milling Machine include the spindle house assembly, flat belt, and limit switches.

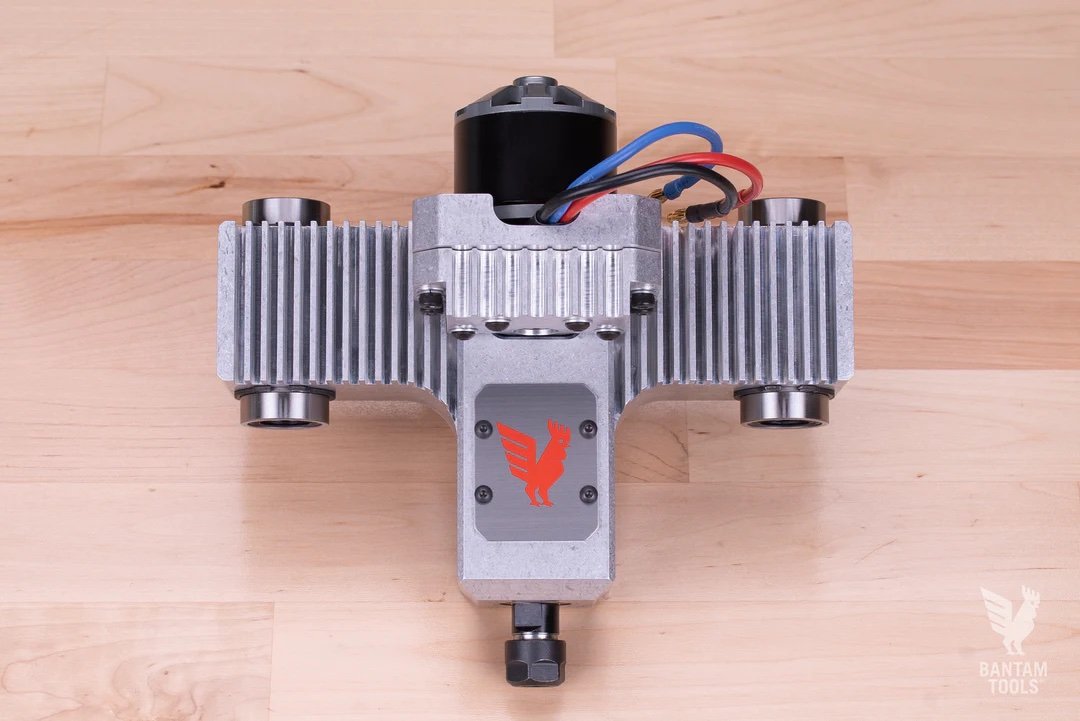

Spindle House Assembly: This part is literally the beating heart of your machine. It features an open motor and houses the flat belt and ER-11 tool holder.

Flat Belt: This component is what turns your Bantam Tools Desktop CNC Milling Machine’s spindle. It’s inside the spindle house assembly and over time it can start to fret (or break apart).

Limit Switches: This component is a calibration sensor that uses a pressure switch to detect the axes on your machine. These switches play a crucial role in the homing process, probing routines, and more.

While the spindle house assembly and flat belt will wear out, there are steps you can take to keep this part at peak performance.

Chip and dust management: Especially when working with materials that generate fine dust (e.g. wood), using the Bantam Tools Desktop CNC Vacuum Attachment is a must. Additionally, taking the time to brush chips off the limit switches can prevent conductivity errors.

Materials you're cutting: We support a number of metals, engineering plastics, and hardwoods. But if you're machining unsupported materials, this will impact the lifespan of your spindle and cause binding along your axes. Using the machine as intended will enable you to get the most out of it.

Speeds and feeds you're programming: Don't get us wrong, the Bantam Tools Desktop CNC Milling Machine is built to take a hit. We want you to be able to fail fast and iterate quickly. Along the way crashes may happen, but if you're constantly programming aggressive speeds and feeds or crashing your machine, this can lead to issues with your spindle.

Re-Tensioning the Flat Belt: Periodically, the Bantam Tools Milling Machine Software will prompt you to re-tension your flat belt. Over time the belt can become loose and if it isn’t re-tightened, this can lead the component breaking prematurely.

Additionally, we care the following spare parts in our store so that you can extras on-hand, just in case:

For more information about clearing and maintenance, head over to our Support Center. If you’re experiencing any issues with a Bantam Tools Desktop CNC Milling Machine or Milling Machine Software, submit a report ticket by emailing support@bantamtools.com. You can find all the replacement parts mentioned in our store under Spare Parts.