Noah Coleman's CNC-Machined Glass Stamp and Motorcycle Cruise Control

It's no secret that the Bantam Tools Desktop PCB Milling Machine is an absolute champ at precisely milling PCBs, but with the wealth of materials it's capable of handling, the buck certainly doesn't stop there. Enter educator Noah Coleman. We first met Noah in 2017 when he was the Technology Coordinator in the Art & Technology Studies Department at the School of the Art Institute of Chicago (SAIC). He was in charge of running the department's digital fabrication lab and helping students realize their digifab projects.

Noah had reached out to share two of the useful tutorials he had created, relating to the Bantam Tools Desktop PCB Milling Machine (at the time called the Othermill):

He's since taken his talents to Ringling College of Art & Design in Florida, and he still enjoys creating projects on his Bantam Tools Desktop PCB Milling Machine and sharing tutorials. Two that he recently shared caught our eye: his custom motorcycle cruise control (seen at top) and his milled glass stamps for use in the Ringling College glassblowing shop he manages. Here's a little about each project, followed by a brief Q+A with Noah.

Motorcycle Cruise Control

I recently went on a longish (1.5 hours one way) trip and I wanted to be able to rest my throttle hand occasionally along the way. I had heard of throttle locks and a quick search on the Google yielded hundreds of results, most of which had a similar design: a bar that grips the throttle and gets pinned against the brake lever, thus holding the throttle in place. I even found a few on Thingiverse. This was such a simple design, I was sure I could make one on my Bantam Tools Desktop PCB Milling Machine.

See Noah's full cruise control tutorial and design files for all the details.

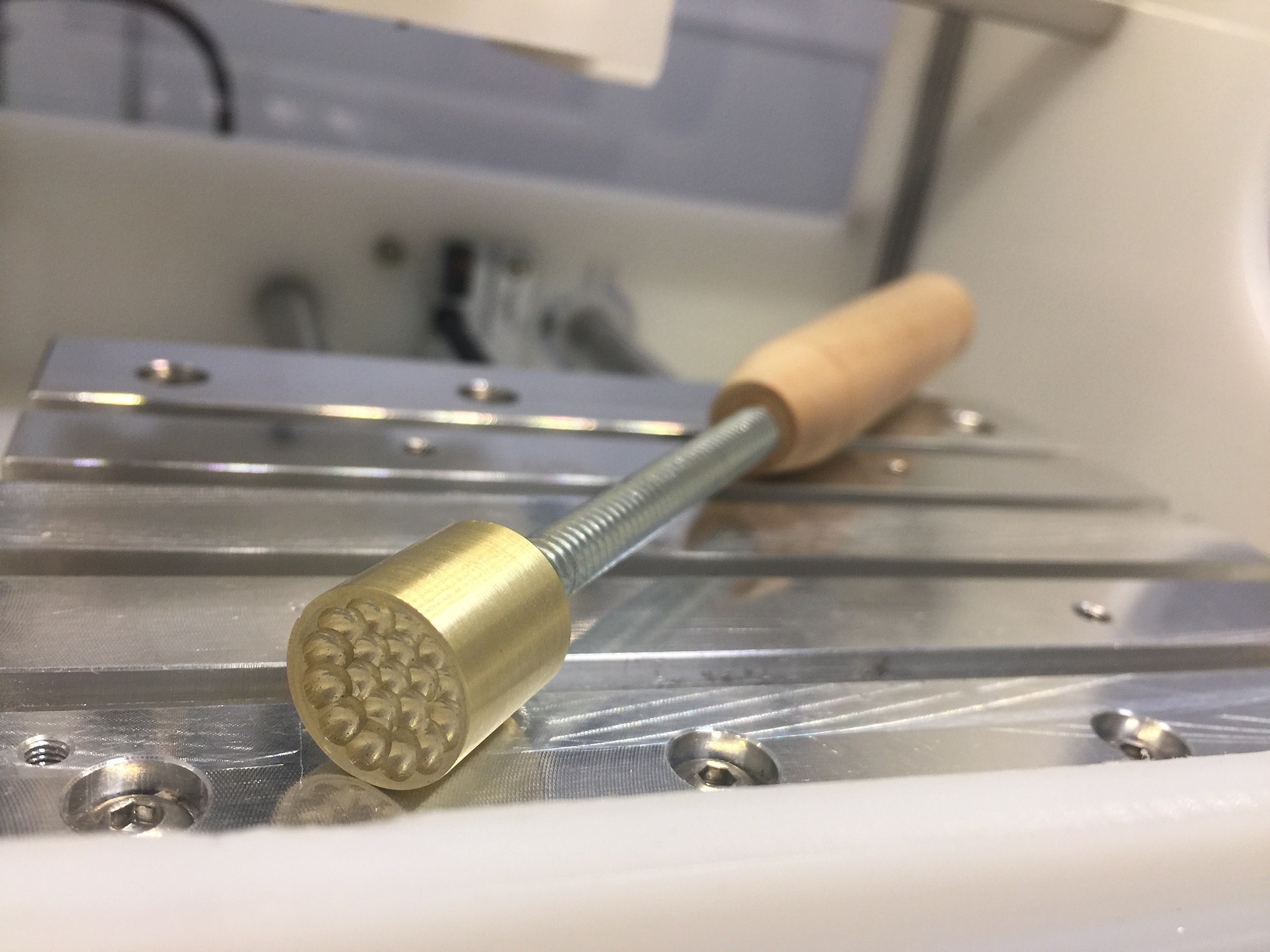

Glass Stamp

Part of my day job involves managing the glassblowing studio at Ringling College of Art & Design and I have been wanting to make something for the hot shop with my CNC. After some thought and a little research, I settled on making some hot glass stamps. I found out they’re called prunts and they’re usually used to stamp designs into blobs of hot glass that have been applied to a vessel or other object.

Where do you have the machine set up right now?

Right now, I have it set up in my office at work. I commandeered an AV cart that I’ve been using as my milling station.

What have you made so far?

I’ve been making all kinds of things: knobs for a jig in the wood shop, a cruise control mechanism for my motorcycle, a magnetic pin holder for my wife, a lamp for my house, textured stamps for glassblowing, you name it!

What's your favorite thing about the Bantam Tools Desktop PCB Milling Machine?

Based on my answer above, I’d say my favorite thing is how versatile it is! I’ve milled PCBs, wood, brass, aluminum, and plastic. I love being able to use a full range of real materials. I gotten into digital fabrication via 3D printing—and I still think 3D printing has a lot of advantages—but the thing I love about CNC milling, in general, is the ability to use so many diverse materials. My favorite thing about my Bantam Tools Desktop PCB Milling Machine, specifically, is how easy it is to use. The WYSIWYG control software makes it really easy to see what’s going on and notice when problems may arise.

What projects do you have in the works? Future projects?

I just finished making a textured stamp for glassblowing, which turned out really nice. I’ve been wanting to make a project where I have to work creatively around the mill’s relatively small envelope. I’m also interested in looking at ways to make larger structures that use milled parts, similar to the moonscape project featured on your blog a while back. I’d also like to try experimenting with different, maybe unconventional, materials. You can keep up with what I’m making on my blog or on my Instagram.

In your time at SAIC, what was the biggest impact you saw the mill have on students?

At SAIC, we were using the mill primarily for circuit boards, and it was really neat to see students take a circuit they’ve been breadboarding and turn it into a nice, tidy PCB. It was also great to see faculty begin to incorporate circuit board design into their curriculum so their students had to go through the process from idea to manufacture.

I think both those things really empowered the students to do things that they wouldn’t otherwise or are impossible (or just ugly) with a breadboard or a perf board with a million jumpers. There were also a few faculty members developing boards specifically for use in their classes. One professor made 555 PWM PCBs for his students, who learned to solder with that board and then used the circuit for projects throughout the class.

Thanks so much, Noah! We appreciate you sharing your projects with the community all you do as an educator!

Got a project or unique usage of the fast, reliable, and precise Bantam Tools Desktop PCB Milling Machine? We'd love to see it! Email us at support@bantamtools.com or tag us on social media with #bantamtools.