Milling PCBs on the Bantam Tools Desktop CNC Machines

With the wealth of materials our Bantam Tools Desktop PCB Milling Machine can handle with ease, the potential of what you can make is endless, but the area where our small-but-mighty mill shines the brightest is in milling PCBs. After all, PCB is our mill's middle name. We put professional precision and reliability directly on your desktop, so the rate at which you prototype is only limited by your imagination, not the return rate of the board house you use. To boot, we've got you covered with a full library of support guides, detailing all aspects of milling PCBs. Here we offer an overview of our PCB-specific guides.

Before we get started, let's take a quick look at what makes our mill so well-suited to milling PCBs. The numbers say it all:

Accuracy: <0.003" (0.0762 mm) per 6" (152.4mm) linear travel

Highest Resolution: 0.000125" / 3.18 microns

Trace & Space: 6 mil / 0.006" (0.1524 mm)

Repeatability: ± 0.001" (0.0254 mm)

With in-house, same-day PCB production, you can:

Save time and money

Quickly find and fix design errors

Accelerate your product development

Finish ahead of schedule and on-budget

General PCB Guides

If you're just getting started, you'll want to check out our general guide on How to Make PCBs on a Desktop Mill. We also recommend SparkFun's PCB Basics if you're brand new to milling PCBs. Below are the general PCB support guides we offer. Click on each guide name to access the full guide.

Design Considerations

There are some important things to consider when designing your board. This guide is intended for people who already have some knowledge of PCB design. We start with the design rule list, and then go into detail about each design consideration, including:

Spacing between traces and components

Vias

Ground/power planes

Trace width

Ways to increase milling speed

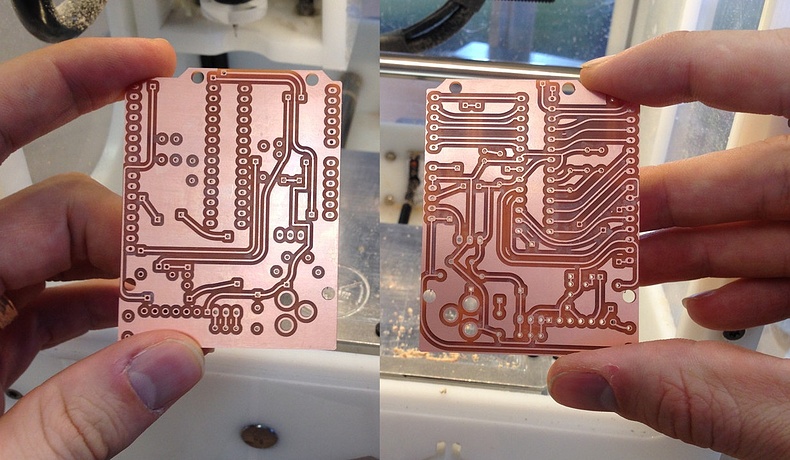

Double-Sided Boards

While single-sided PCBs are simple and ideal to use when possible, many circuits require two sides. Double-sided boards offer a wide variety of possibilities for circuit board designers because they have more surface area and flexibility when routing traces. Using two sides instead of one also allows for a smaller board size overall, which can be important when building small-scale, integrated devices. This guide contains all the information you need to get started milling double-sided PCBs.

Engraving Bit Isolation Milling

Engraving bits are a fantastic alternative to flat end mills for some milling traces and pads. Because engraving bits are tapered, they’re made of more metal and are stronger and less prone to breaking than their end mill counterparts. Even very narrow engraving bits can mill successfully at comparatively high speeds and in only one pass. This makes them a great solution for quickly milling circuit boards with small features, and the recommended option for milling all traces that are too small to be milled with a 1/32" flat end mill. This guideprovides background information on why you might want to use engraving bits to mill PCBs, tips on choosing an engraving bit, and step-by-step configuration details.

Surface-Mount Package Compatibility

Many surface-mount electronic component packages work great with circuit boards made on the Bantam Tools Desktop PCB Milling Machine. Because of their small dimensions, small cutting tools are often required to cut the small traces. This guide lists the maximum tool diameter suggested to cut traces for SMD packages.

Unmillable Area Warnings: Bridged Traces and Skipped Holes

Whenever you mill a PCB, you need to choose tools that are the appropriate size for the features on the board. Choosing tools that are too large can result in some areas not being milled, while choosing tools that are smaller than necessary can increase milling time. Our software’s unmillable area warnings help you identify when you may need to choose a smaller tool. Bridged traces and skipped holes are two of the challenges inherent in milling PCBs. This guide helps you understand, recognize, and avoid bridged traces and skipped holes.

Troubleshooting Your Circuit Board

Is your circuit board not coming out quite right? This page is for you. Here are solutions to common issues, including:

My file renders but won’t cut all the traces.

My through-holes and vias didn’t cut.

All of my traces came out really deep or really shallow.

Some of my traces came out really deep.

When I try to import my Gerber files, they’re all greyed out in the Import Files window.

When I use oval holes/slotted holes/the G85 command, the software won’t recognize my NC Drill file.

Software-Specific PCB Guides

In addition to the general guides listed above, we also offer a full array of support guides covering different circuit design software options.

For starters, check out the following guides.

Creating Circuits with EAGLE

EAGLE is powerful software for making circuit boards, and its creators have made it free for boards under 4"x3", which works great for most projects. The Bantam Tools Desktop Milling Machine Software can import many kinds of files, but EAGLE is the most common for circuit boards. The support for EAGLE is so complete that all you have to do is drop an EAGLE .brd file into the software and click Cut. Our EAGLE guide and our Creating Circuits with EAGLE guide show you how.

Gerber Files

Gerber is a 2D vector image file format, and it’s the industry standard for containing information about a printed circuit board. If you’re going to get your PCB made by a circuit board manufacturer, a set of Gerber files is what they will ask for. Gerber files can describe the copper traces, component placement, solder masks, silkscreen markings, and many other layers or aspects of a PCB. The software can import Gerber files that represent a PCB’s traces and outlines. Our Gerber guide gives you all the details.

Aside from our general EAGLE and Gerber guides, we also offer dedicated guides for the following PCB design software options:

And if you still have questions or need assistance, we're always here to help. Reach out to us at support@bantamtools.com.