Erik Beck Breathes Life into Inanimate Objects Using CNC Machining

“At the end of the day, taking something from your imagination and making it a physical thing you can hold has always felt a bit like magic to me,” shares special effects mechanic Erik Beck. We couldn’t agree more. Specializing in mechanical FX and animatronics, Beck’s job, in essence, is to make the inanimate move. He’s worked on all kinds of interesting projects, including the Chucky TV series and the Foo Fighters horror movie Studio 666. Digital fabrication has allowed him to take his craft to the next level with its precision, repeatability, and rapid prototyping capabilities.

Beck got his start in 2007 when he cofounded a YouTube channel called Indy Mogul, where he would teach viewers how to create Hollywood-style FX for $50 or less. The fun part is that he wasn't an expert and was basically teaching himself as he was teaching the audience—resourcefulness at its finest. Needless to say, he learned a ton over the years and became a sort of low-budget jack-of-all-trades FX person.

After Indy Mogul, Beck spent the next decade running a small production company with his best friend, incorporating “practical FX” into their projects. At that point, he decided to narrow his focus and hone in on a specialty, noting, "Building things has always brought me the most joy, so I decided to focus on FX, which led me to mechanical FX and animatronics." He currently works at KNB EFX, a respected effects studio that has been recognized for their work on The Walking Dead, Dune, The Chronicles of Narnia, Reservoir Dogs, Men in Black, and Army of Darkness, among hundreds of others. What exactly does Beck do there? He boils it down for us: “Since my specialty is mechanical FX, I only get to work on the projects where something has to move. So like an animatronic animal, or zombie, or a big creature suit that has elements that have to move. I also sometimes design rigs for specific FX shots, like a bone breaking through the skin or an exploding head. My job is to make pretend things move and come to life.”

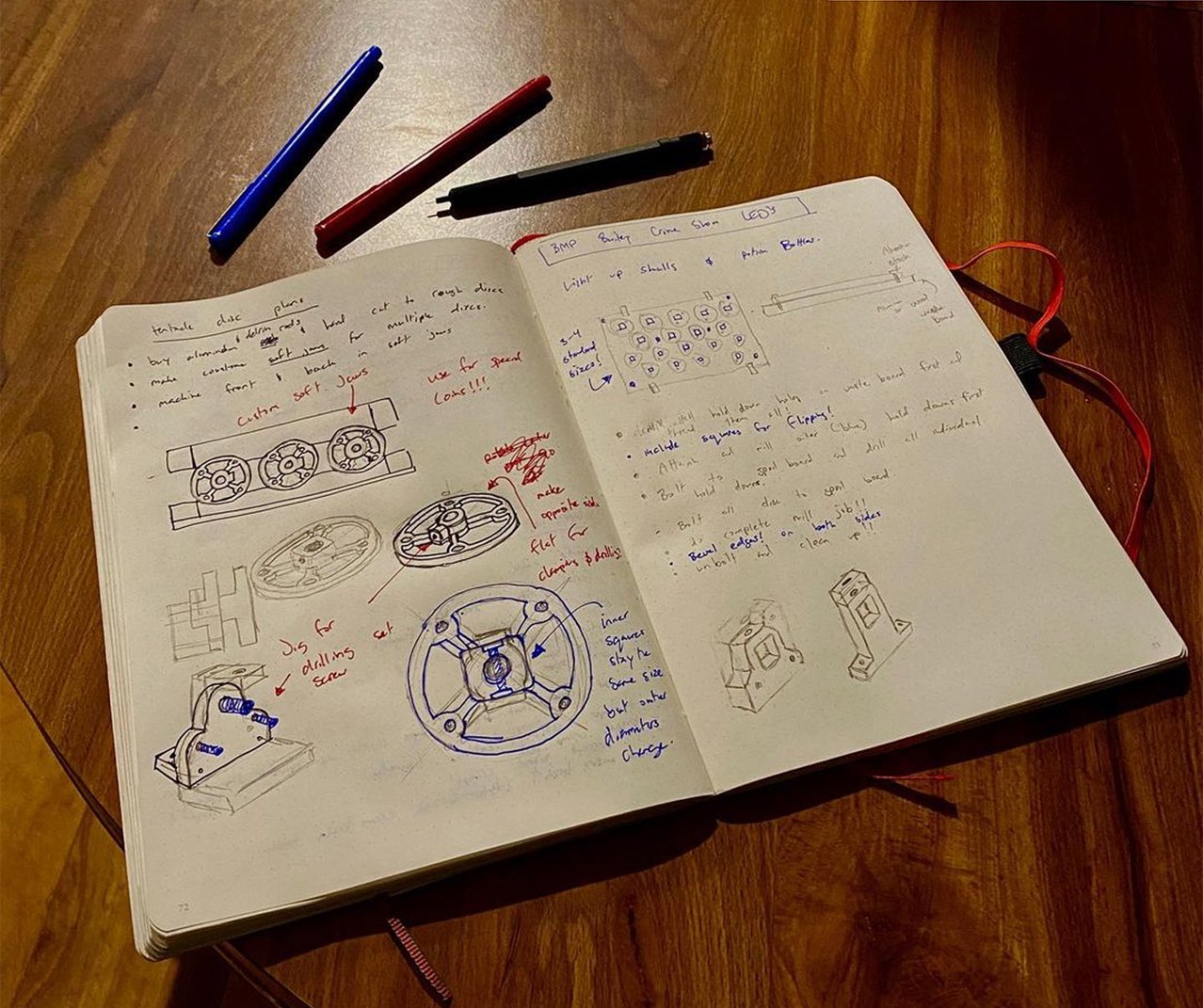

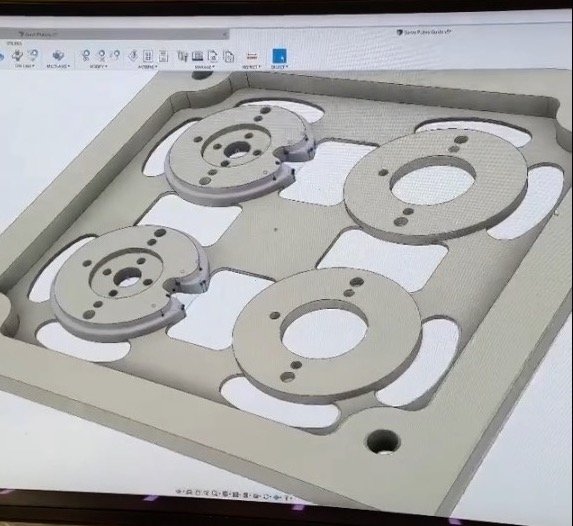

Beck’s workflow has long started in Fusion 360, and he got his foray into digital fabrication through the gateway—3D printing. But because he makes parts that have to withstand hours of action, being limited to printing only in plastic is a limiting factor. Then he added a Bantam Tools Desktop CNC Milling Machine to his tool arsenal. He shares, “The Bantam Tools Desktop CNC Milling Machine has allowed me to take a workflow I was already comfortable with (Fusion 360) and make much stronger and more precise parts out of aluminum and Delrin. There’s, for sure, a learning curve to make the jump from 3D printing to CNC, but I feel like the Bantam Tools machine, software, and support make it as easy as possible.”

Now he typically designs the whole project in Fusion 360 and then uses a couple of FDM printers to make test parts out of PETG plastic. Using those parts, he prototypes to work out the kinks before machining final parts in aluminum or Delrin on the Bantam Tools Desktop CNC Milling Machine. Beck adds, “It's great because the Bantam Tools software works so well with Fusion 360, so I can export the STL files for the 3D-printed test parts, tweak them, then program the CAM to CNC the parts in the same program.” He’s used the Bantam Tools Desktop CNC Milling Machine to make parts for everything from full animatronic heads to small animatronic animals and monsters of all shapes and sizes.

Beck left us with a salient nod to the traditional tools of the trade in FX and how digital fabrication fits in: “I'm lucky enough to have access to some great old manual milling machines at our shop and would love to be able to jump on them and make beautiful parts every time, but I'm not there yet skill-wise. I'm a much better designer than I am a machinist at this point, and using digital fabrication allows me to cheat a bit and get the precision parts I need faster and better than I could make by hand.”

Though Beck’s current work projects are too top secret to share, we’ll definitely be keeping an eye on his Instagram feed to peep the latest.

About Erik Beck

Erik is a pioneering digital producer with over 11 years of experience developing and producing award-winning digital content. He builds audiences and robots—lots of robots. Follow him on Instagram to see his latest creations.

At Bantam Tools, we build desktop CNC machines with professional reliability and precision to support world changers and skill builders. For the latest Bantam Tools news, sign up for our newsletter. If you’re interested in adding a Bantam Tools machine to your workflow you can order directly from our online store or request a quote.