We're Live! The Bantam Tools Desktop CNC Milling Machine is Now Available

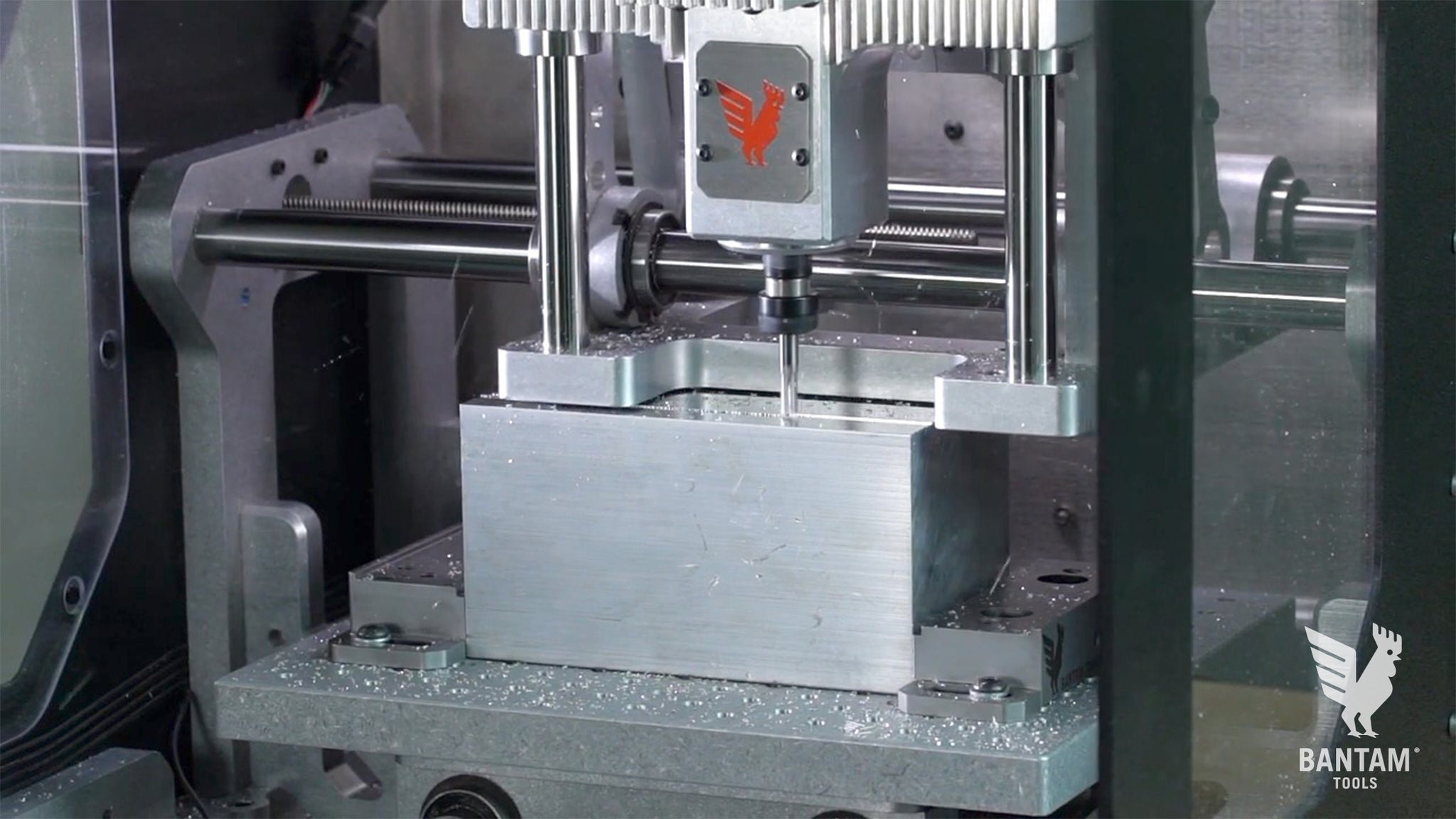

making aluminum parts is fast & easy

It was a big day at the Bantam Tools HQ, today! In case you missed it, we launched the Bantam Tools Desktop CNC Milling Machine and to celebrate, we held a livestream event this afternoon. A huge thank you to everyone who was able to make it. We enjoyed fielding your questions and connecting with you all. If you missed the livestream, here’s a replay along with some of the top questions.

top questions from the livestream

What’s the price?!

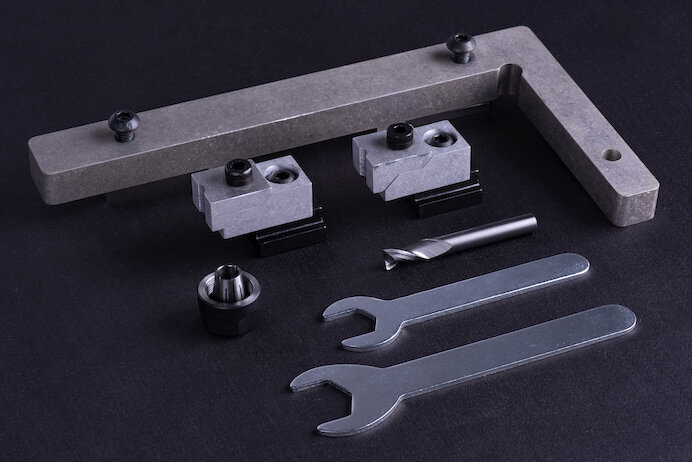

Until January 1, 2021, we’re offering the new Bantam Tools Desktop CNC Milling Machine at a discounted price of $3,599, down from $3,999. We’re also offering financing for the machine. Plus you can earn cashback rewards through our referral program. For every friend you refer who also buys a Desktop CNC Milling Machine, you’ll get $100 back––and your friend will save $100 on their purchase as well! Head over to our referrals page to learn more.Where is the machine made?

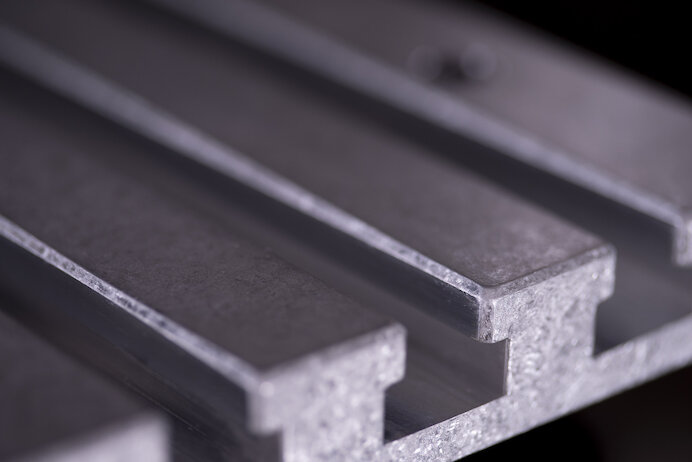

We’re proud to say that most of the parts and along with the entire machine frame is made at Bantam Tools HQ in Peekskill, NY––and 100% of the machine is assembled in-house.

Does it use coolant? Can it cut steel?

While this machine can cut steel, we don’t recommend machining it for an extended period of time. The Desktop CNC Milling Machine is optimized for machining aluminum. Because the lowest spindle speed is 10,000 RPM and steel requires a much lower surface feet per minute compared to aluminum, you need to run smaller tooling when machining steel (3/16" and below). There’s no coolant system on the machine, so take great care if you do. We’ll be releasing a full list of speeds and feeds for various materials once we begin shipping in August!

Tell us more about the software subscription for the new Bantam Tools Milling Machine Software.

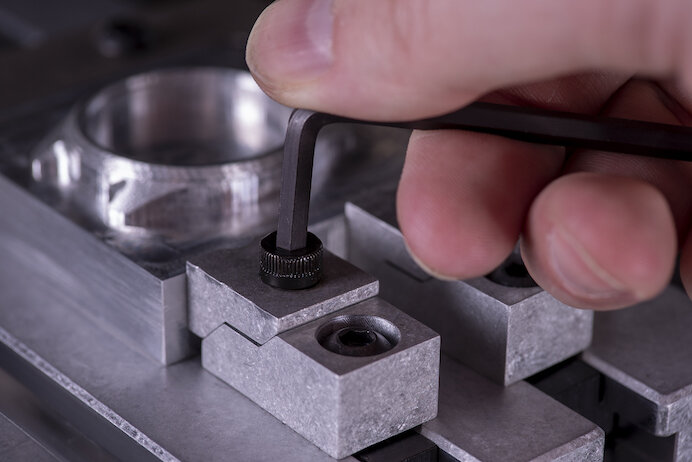

Every Desktop CNC Milling Machine comes with our fully-featured Bantam Tools Milling Machine Software. This includes material probing and automatic stock location routines as well as SVG support. In addition, you’ll also get a 30-day free trial of our subscription software, which unlocks even more professional features like advanced material probing routines and feed rate override. We decided to release this subscription model in order to support monthly feature releases to subscribers. As a software subscriber you’ll also get priority tech support, and curated Bantam Tools projects. Stay tuned, we’re going to be diving into this later this week!

Can you mill PCBs using the Desktop CNC Milling Machine?

While the Desktop CNC Milling Machine is optimized for prototyping in aluminum, we want to continue to support our users interested in making electronics. In August, we’ll be releasing PCB Milling Support for software subscribers. If you’re a PCB Milling Machine owner, you’ll have access to this feature for free.

Machine Specs

Overall Dimensions: 19.8” × 20.9” × 19.4”

Build Volume: 7” x 9” x 3.3”

Max Traverse: 250 in/min

Spindle Speed: 10,000-28,000 RPM

Repeatability: +/- .001”