Bantam Tools CNC Community Q&As

As you tackle new projects with your Bantam Tools Desktop CNC Milling Machine, we want to provide you with the resources you need to continue your CNC journey. Every other week, we’ll be hosting a Q&A to cover helpful tips and techniques when working with the Desktop CNC Milling Machine and Bantam Tools software. You're always welcome to reach out to us on social or through our support center if you have questions, but we wanted to give you another space to have your questions answered.

Note: During these Q&As, we’ll be using Fusion 360. If you prefer to use a different CAD/CAM software that’s totally fine—the Bantam Tools software supports G-code, NC, and SVG files. But if you’d like to use Fusion 360, you can download a free trial of the software for professional use or the free version for personal use.

What is CNC Machining?

We take pride in seeing our desktop CNC machines being used by professionals and hobbyists alike. And it's been exciting to learn that many of our Desktop CNC Milling Machine users are just beginning their journey into CNC. But we also know that it can feel overwhelming when you’re just starting out. In our first CNC Q&A, we drill down into the basics and cover a wide range of CNC-related topics to introduce you to key terms and concepts that will help you learn the fundamentals of CNC machining.

Video Overview

How do you explain what a CNC milling machine is? (8:58)

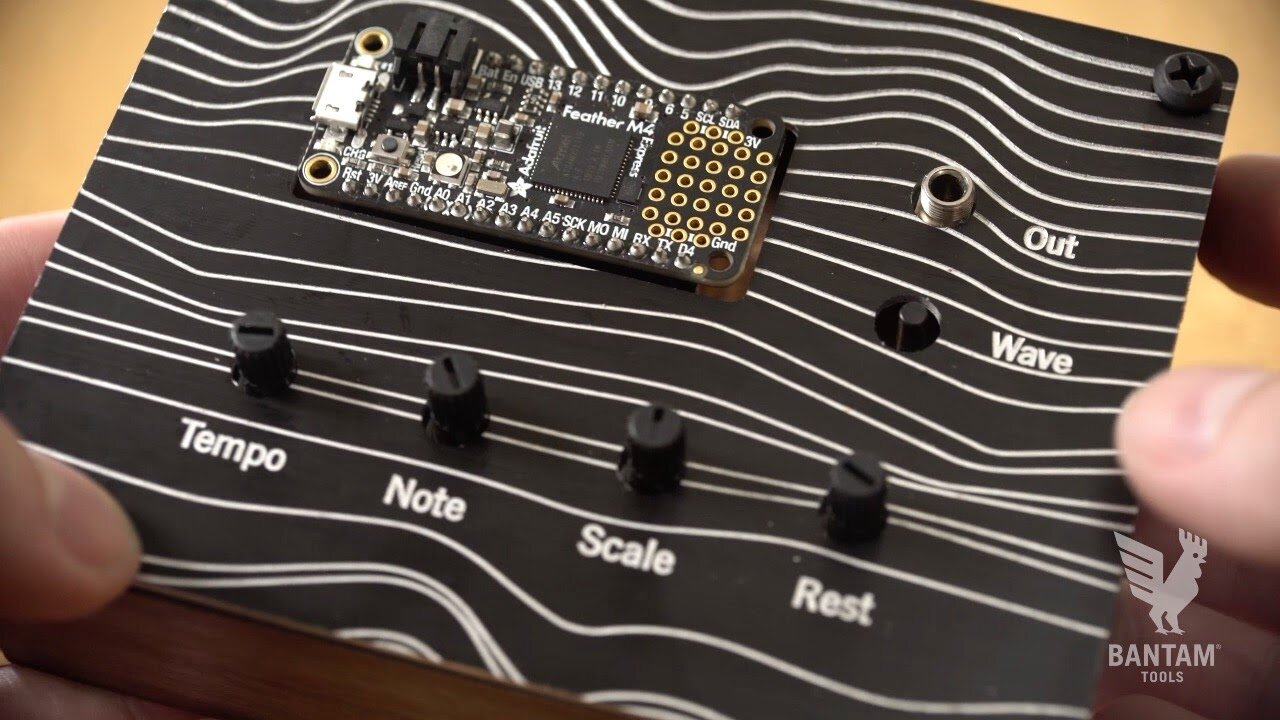

Why is a desktop CNC milling machine useful? What can I do with it? (14:31)

What is CNC milling, anyway? Specifically, what is three-axis machining? (22:37)

Working with different file formats. What's an SVG and why is it useful? (30:05)

How the Bantam Tools software makes it easy to mill a design (30:56)

Basics of "speeds & feeds" - the nuances of the way you set up your project (34:30)

Speeds & feeds override feature in the Bantam Tools software (41:11)

Lowering the barrier to CNC machining using our Getting Started Projects (42:40)

It's like cooking! (44:33)

What's Z-height? What's a z-crash? (48:54)

What is thread milling? (1:00:41)

How to get in touch with us (1:03:37)

Designing CAD in Fusion 360

Before you can start machining with your Desktop CNC Milling Machine, you'll need to create a design. For this, you can use a CAD/CAM software like Fusion 360. In this CNC Q&A, we walk you through Fusion 360's Design workspace, downloading the Bantam Tools Tool Library, and creating a new CAM setup to help you become more familiar with the tools available.

Video Overview

File management and layout in Fusion 360 (6:24)

Sketching in the Design workspace (12:00)

Downloading and importing the Bantam Tools Tool Library (33:38)

End mill geometry overview (35:04)

Creating a new Setup

Setting work coordinate system (54:34)

Orienting your model (1:05:25)

Selecting 3D adaptive clearing toolpath (1:13:37)

Programming CAM in Fusion 360

Okay, you’ve designed your CAD model—now what? In this Q&A, we pick up where we left off in our previous session to dive into programming toolpaths in Fusion 360. With so many toolpaths to choose from—and even more boxes to check off—it can be difficult to know where to begin. But don't worry, we walk you through programming your toolpaths one tab at a time.

Video Overview

Recap creating a setup in the Manufacturing workspace (7:21)

Programming adaptive toolpath (17:26)

Tool tab in programming pop-up window (20:08)

Geometry tab in programming pop-up window (28:06)

Heights tab in programming pop-up window (40:45)

Passes tab in programming pop-up window (46:56)

Troubleshooting stock leftover (54:17)

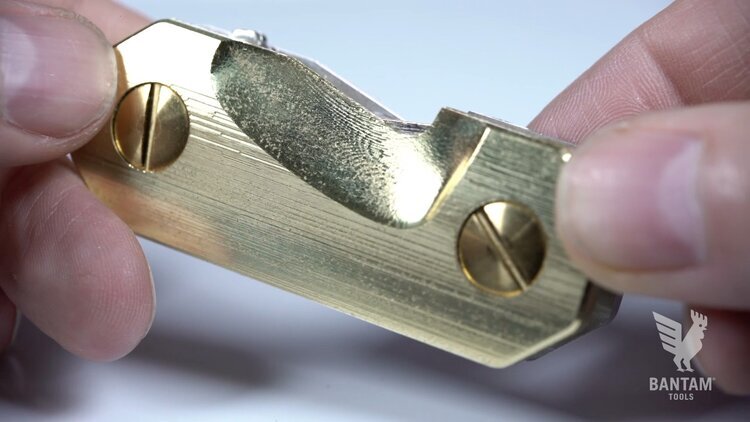

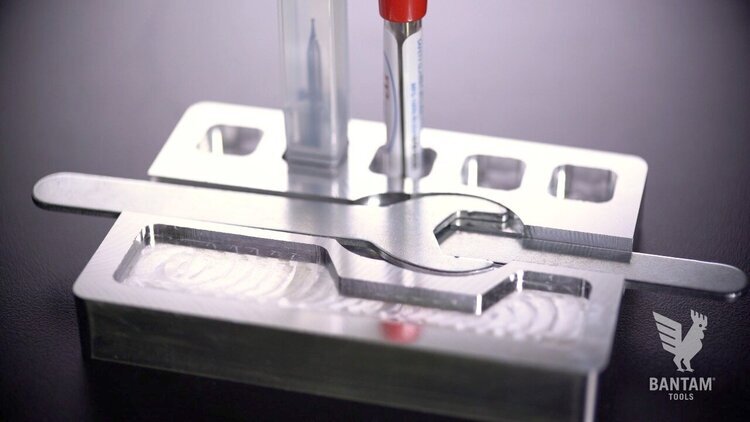

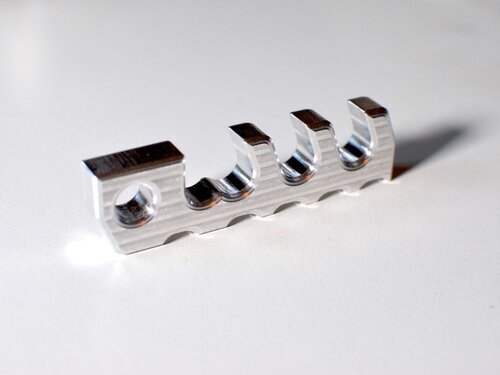

Check out the fire starter survival tool (57:04)

Post-process G-code (1:01:30)

Import G-code file into Bantam Tools software (1:06:13)

Additional Resources

Here’s a list of helpful resources we mentioned during the Q&A’s. If you have further questions about operating the Desktop CNC Milling Machine or are looking for projects to help you continue to learn the basics of CNC machining, check out our support center!

NYC CNC’s Fusion 360 for Beginners

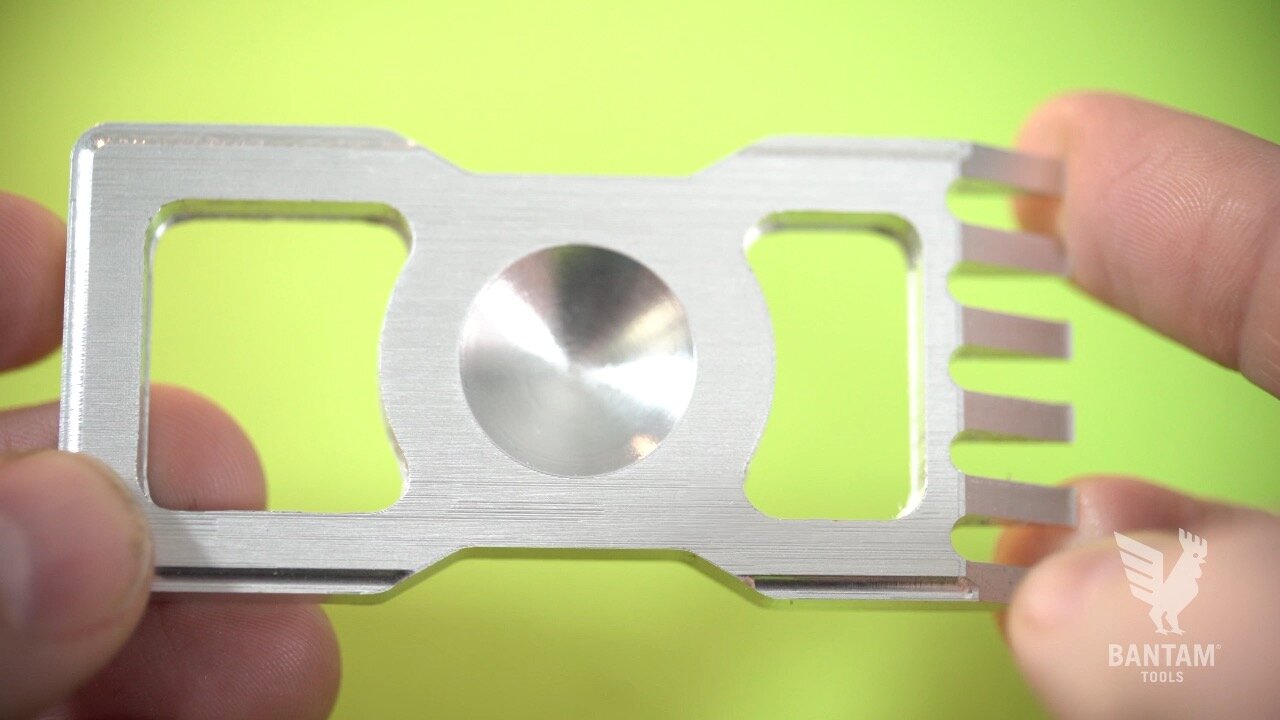

Aluminum Rings PCB mill project

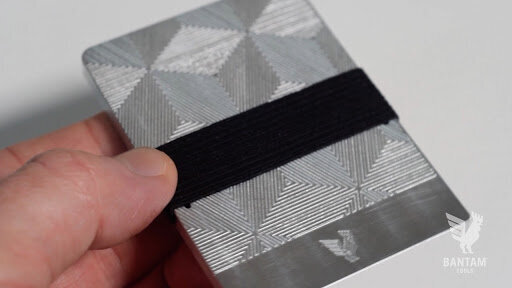

Bantam Tools Desktop CNC Milling Machine Getting Started Projects

Send us your questions at resources@bantamtools.com and we’ll answer them during our next CNC Community Q&A!